HA inspections – Sugar Dust HA Upgrade

In line with our client’s ongoing commitment to hazardous area compliance, a review of their dust processing system identified the potential for hazardous area zones to expand under specific fault conditions during certain process stages. This led to the reclassification and extension of the existing hazardous areas to cover these potential risks.

As a result, previously unaffected safe-area devices required upgrading to hazardous area-rated devices, ensuring compliance with the latest standards.

ARA’s electrical engineering and trade teams were engaged to deliver a complete design and upgrade for the extended zones. This large-scale project leveraged our expertise in hazardous area engineering to create solutions that met all regulatory standards while adhering to tight shutdown windows.

Our team produced a comprehensive hazardous area dossier, inspection sheets, and ensured all machinery was operational with full sign-off from hazardous area inspectors. The project was completed within the planned shutdown timelines, minimizing production downtime as scheduled.

The project included the upgrade to hazardous area equipment of

- 3 Jelly dust Mogul upgrades

- Process instrumentation upgrades with new iS cabling

- iS calculations and design

- New HA motors including new servo drives

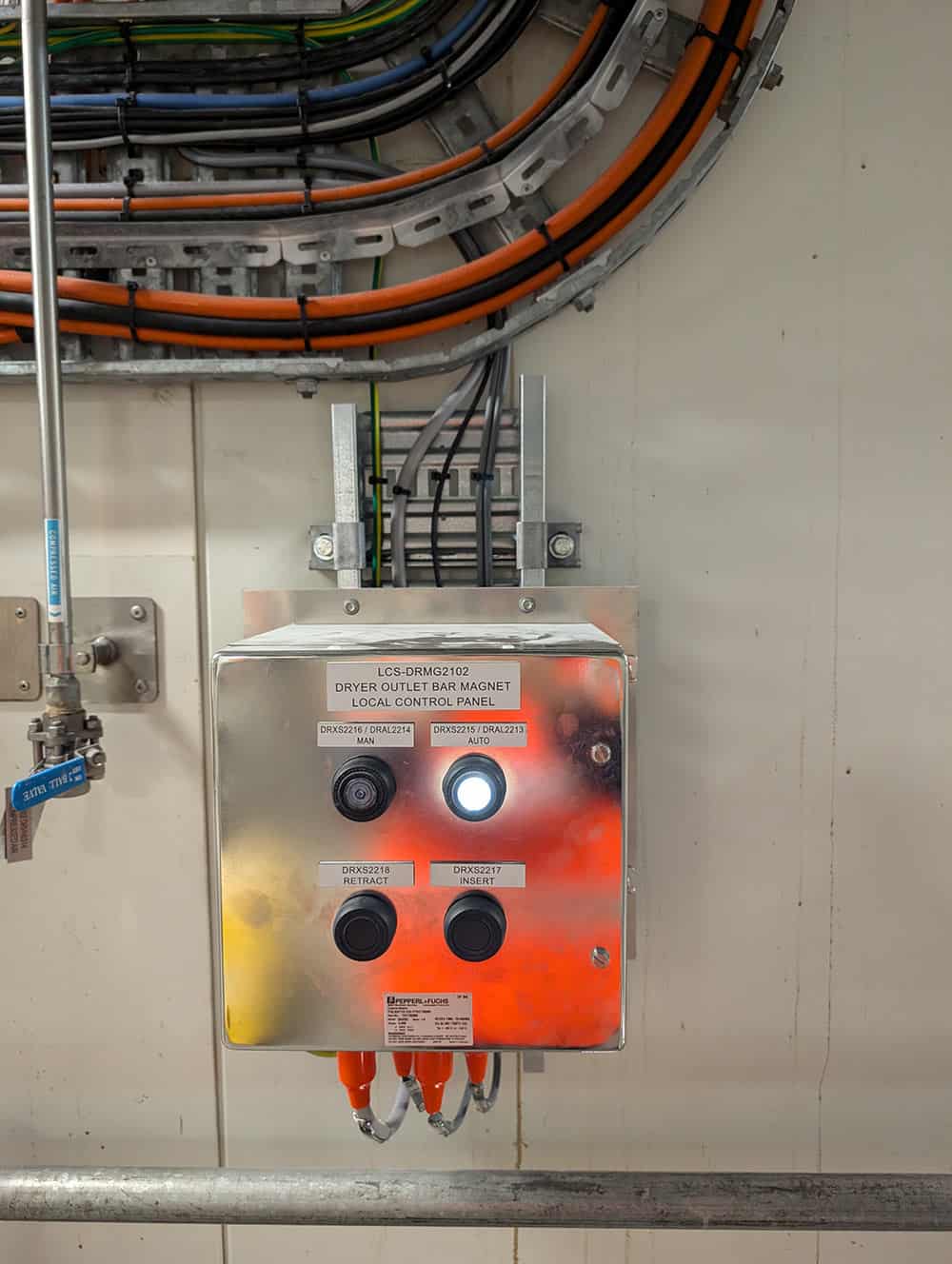

- All new dryer control stations

- New Extd control panels, design, fabrication, and installation

- Detailed HA inspections and inspections

- Upgrade modified drawings