Demystifying Hazardous Area Classification: What You Need to Know

In industrial environments, safety is paramount. Whether you’re operating a chemical plant, a refinery, or a manufacturing facility, understanding and properly managing hazardous areas is crucial to ensure the safety of personnel and protect against potential risks.

One key aspect of industrial safety is Hazardous Area Classification (HAC). But what exactly is Hazardous Area Classification, and why is it essential? Let’s delve into this critical topic to shed some light on its significance.

Understanding Hazardous Area Classification

In simple terms, Hazardous Area Classification involves identifying and categorizing areas within a facility where the presence of flammable gases, vapors, liquids, combustible dusts, or ignitable fibers could pose a risk of fire or explosion.

The Importance of Hazardous Area Classification

- Risk Mitigation: By accurately classifying hazardous areas, organizations can implement appropriate safety measures to mitigate the risk of fire and explosion. This includes selecting and installing suitable equipment and implementing safety protocols to minimize the likelihood of ignition.

- Compliance: Adhering to Hazardous Area Classification standards and regulations, such as those outlined in documents like the National Electrical Code (NEC) or the International Electrotechnical Commission (IEC), is essential for ensuring compliance with industry standards and legal requirements.

- Worker Safety: Hazardous Area Classification helps protect workers by providing clear guidelines on safety protocols, training requirements, and the use of personal protective equipment (PPE) when working in hazardous environments.

The Process of Hazardous Area Classification

- Identification of Hazardous Substances: The first step in Hazardous Area Classification involves identifying the substances present in the environment that could pose a risk of fire or explosion. This includes flammable gases, vapors, liquids, combustible dusts, or ignitable fibers.

- Assessment of Probability and Severity: Once hazardous substances are identified, the next step is to assess the probability of their presence and the potential severity of any ignition event. Factors such as ventilation, temperature, and the presence of ignition sources are considered during this assessment.

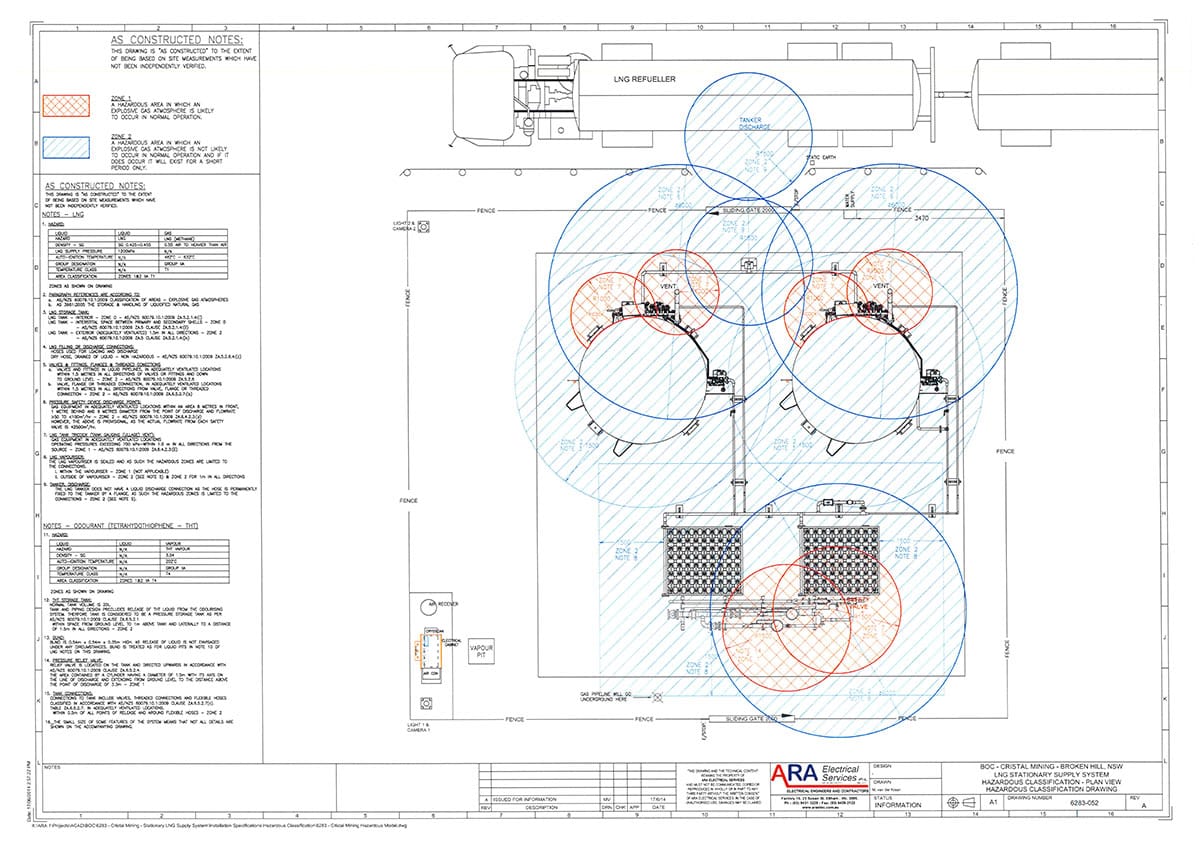

- Zoning and Classification: Based on the assessment, the facility is divided into zones or areas based on the frequency and duration of the presence of hazardous substances. These zones are classified according to specific criteria outlined in relevant standards and regulations.

- Selection of Equipment and Controls: Finally, appropriate equipment and controls are selected and installed in each classified zone to ensure the safety of personnel and prevent ignition sources from causing a fire or explosion.

Conclusion

In conclusion, Hazardous Area Classification plays a critical role in industrial safety by identifying and categorizing areas where the presence of flammable substances could pose a risk of fire or explosion. By properly classifying hazardous areas and implementing appropriate safety measures, organizations can mitigate risks, ensure compliance with regulations, and protect the safety of their personnel.

At ARA electrical services, we understand the importance of safety in hazardous environments. Our team of experts specializes in Hazardous Area Classification services, helping organizations identify and manage risks effectively. Contact us today to learn more about how we can support your safety initiatives and ensure compliance with industry standards. Stay safe!