Hazardous Area Compliance

A large international chemical processing company was advised by their insurer that a compliance audit of their manufacturing sites was required, specifically their compliance with the Hazardous Area Standards for equipment operating in potentially explosive atmospheres.

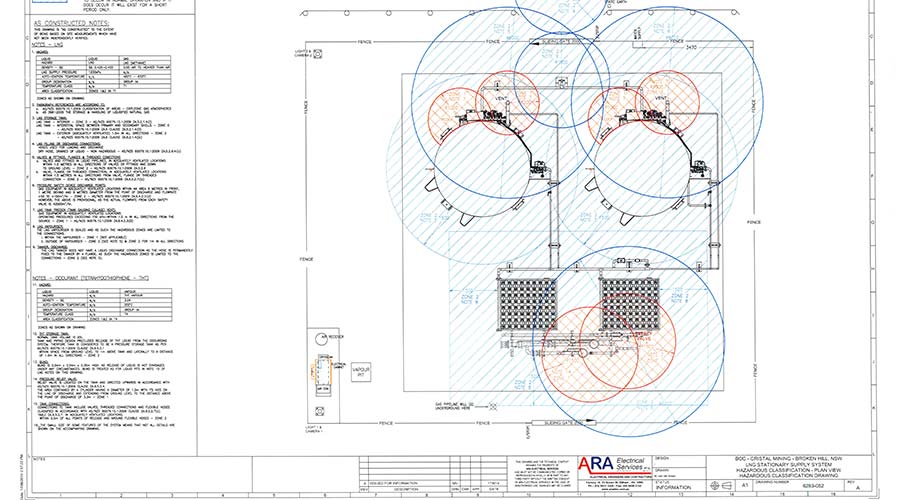

ARA were contracted to develop the sites “Hazardous Area Verification Dossier”, review and update the sites Hazardous Area Classification Documentation and Drawings and clearly identify the hazardous zones, gas groups and temperature classes based on the chemicals present and compounded in the process.

Once the Classification was complete a detailed inspection in accordance with AS/NZS60079 for all items of electrical equipment located in the hazardous areas was conducted. As with many plants, over years of operation, equipment and installation techniques change and a significant number of non-compliances were identified.

ARA prepared an extensive non-compliance report allocating a grade to each non-compliance issue ranging from a “Grade 1” for issues that present an immediate safety threat to personnel, plant and equipment down to a “Grade 3” where the non-conformance is a technical non-conformance with little or no threat to safety and recommended for rectification during the next maintenance cycle.

As part of the report a “cost to rectify” budget was also given to each item to assist our client to commercially manage their way through their move to full compliance.

ARA has Certified Hazardous Area engineers, designers and electricians who were able to rectify, immediately, any safety issues in consultation with the client as they were identified.

On completion of the classification, inspection and rectification activities along with the collection of the required certificates and supporting documentation a site “Hazardous Area Verification Dossier” was formalised and located on site for ongoing management of the hazardous area equipment.